Introduction

While we are continuous helping companies adapt to the industrial changes with digital transformation, the progress of industrial revolution never stops since the 1800s. Through centuries of development of the power, devices, and new technologies, we are now leading to industry 5.0. What is the fifth industrial evolution and what are the benefits of industry 5.0? Let us find out in this article.

Industrial Revolutions

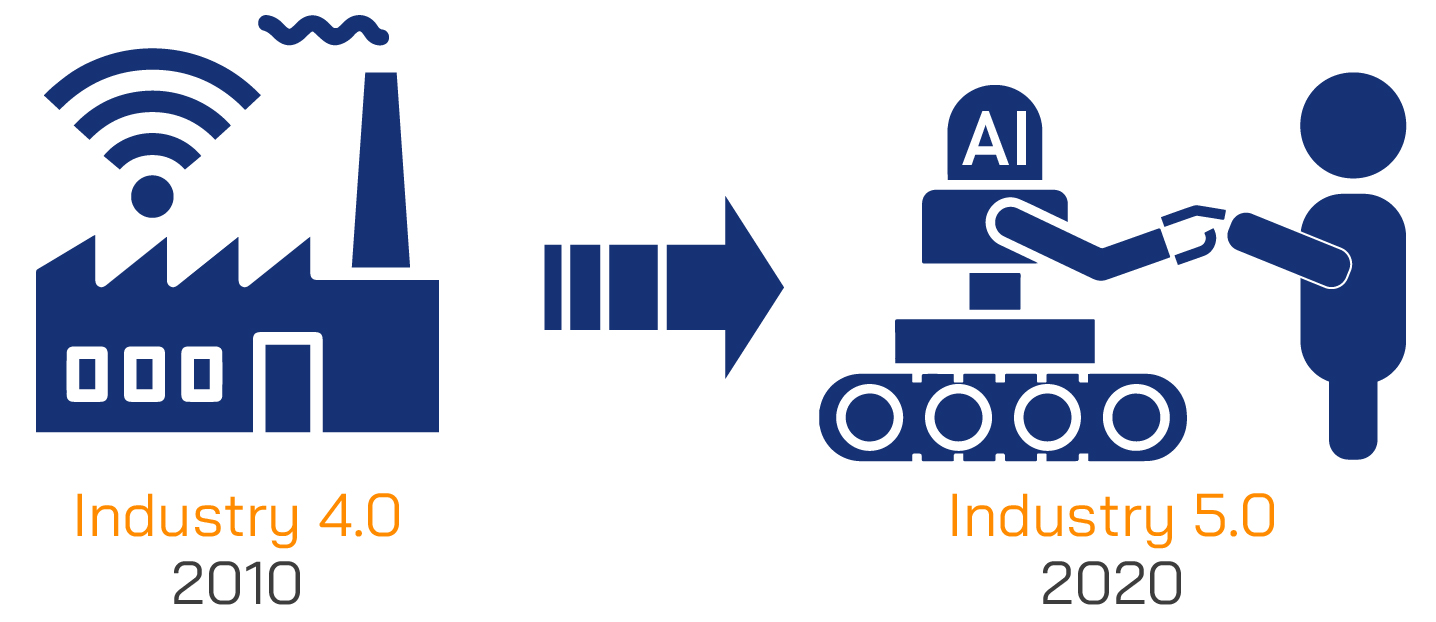

Industry 1.0 began with the development of the mechanization via steam and power engines. Industry 2.0 made use of electricity to implement mass production with assembly lines. Industry 3.0 applied industrial computers and electronics to enable automatic production with programmable controls. With advanced technologies of Machine Learning (ML), Artificial Intelligence (AI), and Internet of Things (IoT), Industry 4.0 integrated enhanced communication and automation with near-real-time connectivity to improve the process, reduce production cost, and make better quality management. Industry 4.0 is still happening while people already talk about industry 5.0…

What is Industry 5.0

Industry 5.0 is the reintroduction of humans and minds into the industrial structure to have human-robot collaboration, and sustainability. In addition to utilizing smart manufacturing with human-robot interaction, it aims to further benefit the employees and the entire society.

Industry 5.0 emphasizes three core elements: human-centricity, sustainability, and resilience.

Human-centricity

Humans are the core of this revolution, not marginalized as some people have predicted. The machines shall serve us, not the other way around. Reintroducing the human element into the process brings the soul back to the manufacturing. The imagination and flexibility of the human worker is enhanced by utilizing the advanced technologies and collaborative robotics.

Sustainability

With the growing emphasis on sustainable energy and reducing carbon emission around the globe, it is necessary to adopt green solutions such as the implementation of circular processes to reuse/recycle natural resources and reduce waste/environmental damages for socio-ecological sustainability.

Resilience

Resilience refers to the demands of strengthened production and supply chain robustness. It must be flexible enough to deal with the disruption, unforeseen situation, unpredictable external force. Organizations has to engage in planning exercises and apply digital technologies to identify optimal alternative paths for the abnormal event.

The Benefit of Industry 5.0

By returning manpower to factories, Industry 5.0 aimed to deliver a tailored customer experience in a new sustainable way. See the benefits below.

Cost Reduction

With the collaboration of humans and robots, robot’s precise operation and human’s cognitive ability and critical thinking generate optimized manufacturing with better efficiency and enhanced productivity. With better-interconnected systems, it can further lower the manufacturing costs, and become more competitive.

Sustainable Solutions

Industry 5.0 considers the protection of the environment as a priority. By being more efficient and productive, the resources can be saved. Furthermore, Industry 5.0 helps manufacturers focus on environmentally friendly solution to protect the ecosystem.

Mass Customization and Personalization

The collaboration between humans and robots helps to accomplish mass customization at scale. It results in deeper customer engagement and satisfaction via better customization experience for personalized and exclusive goods.

Conclusion

Industrial revolution will continue to evolve with the change and make industry adapt the transformation to grow. Human, personalization, and sustainability will continue to play a vital role working along with the latest technologies of IoT, AI, ML, etc. Industry 5.0 is expected to bring about environmental benefits and tremendous growth of productivity via human-robot collaboration.